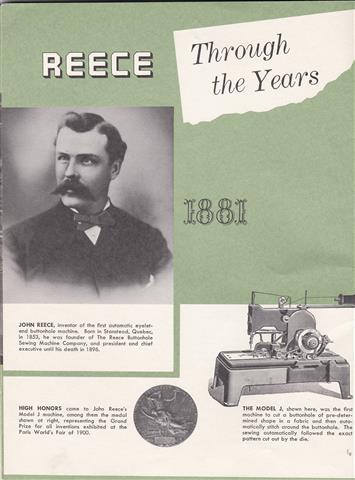

John Reece English

From John Reece to the Reece J. Buttonhole machine.

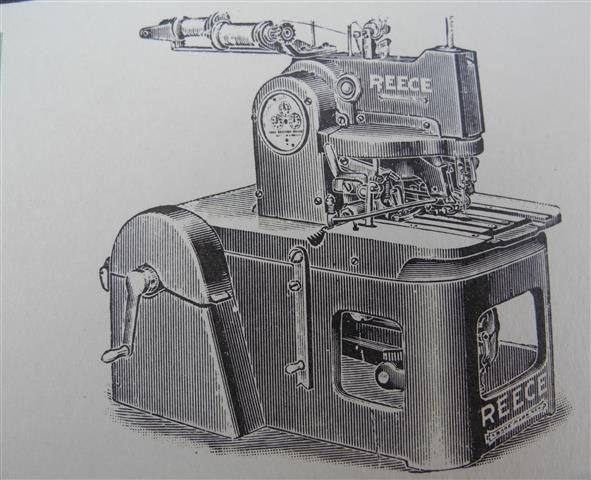

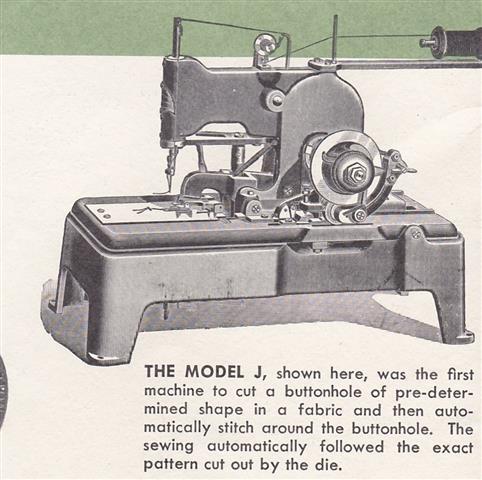

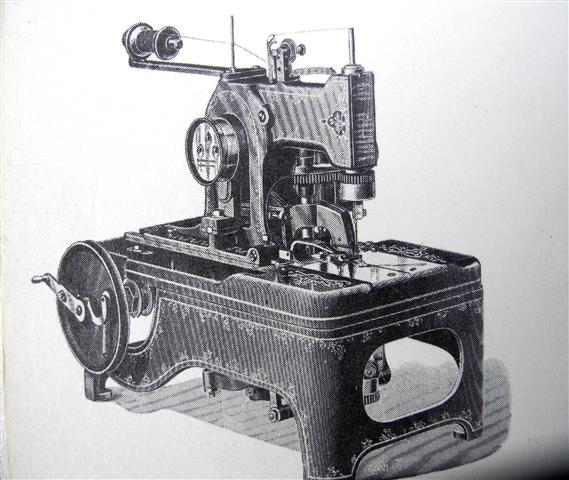

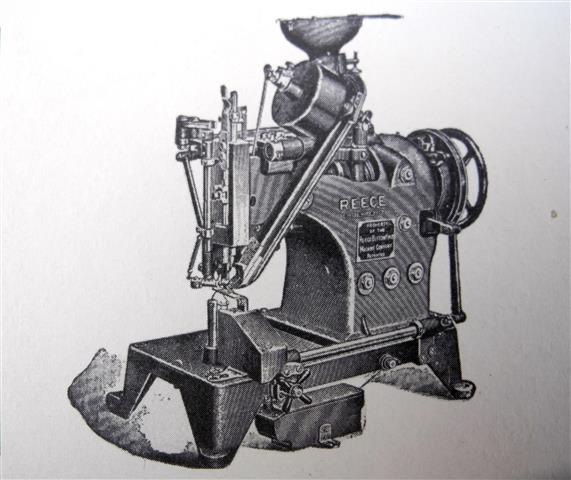

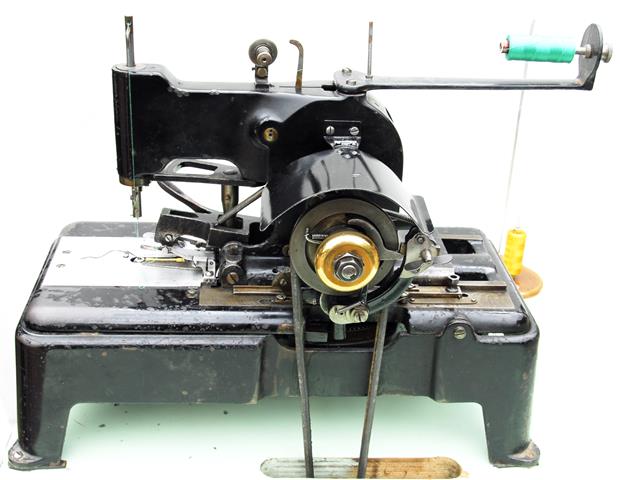

Anniversary 75 years of the Reece buttonhole machines.Reece J. was the original model of the eye buttonhole machine.

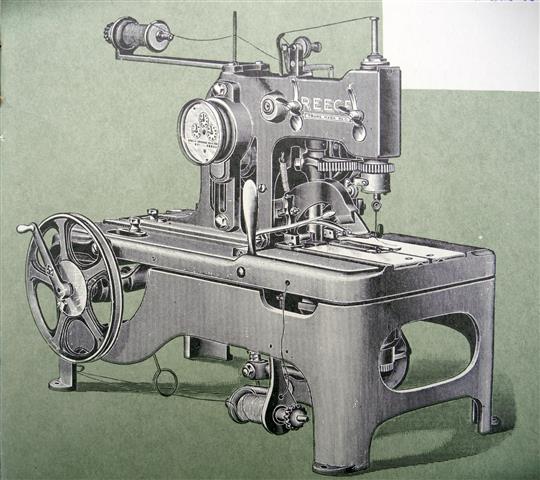

Reece Rapid.

Searching on the internet for information about my Reece Rapid buttonhole machine, I found a You Tube video with a working Reece J. buttonhole machine made by Mr. Jean Mémain.

After some searching and writing I had contact with the French owner of this machine.

After another few weeks of mail and telephone contact, the owner and I came to an agreement that I could purchase this very rare machine.

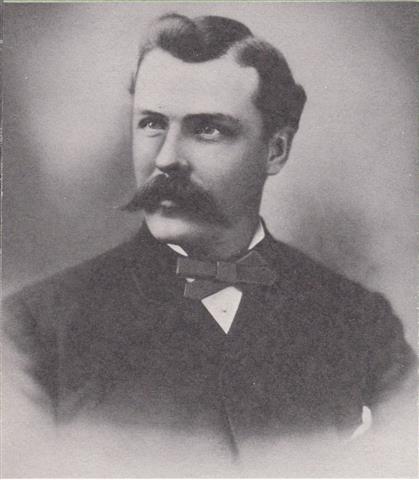

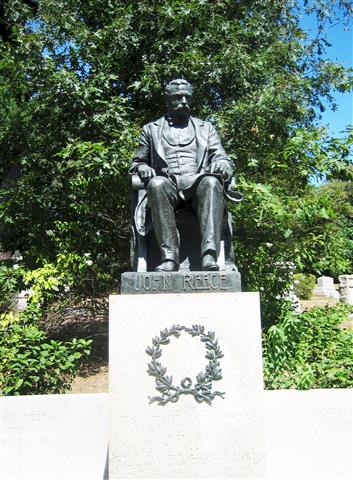

Who was John Reece.

John Reece was born in 1853 in Stanstead Quebec Canada, and died in 1896.

At the age of only 19, he began his entrepreneurial activity.

Together with his partner Morill, he opened a small factory which was connected to a mechanical workshop in rock Iceland (Quebec Canada.).

Two years later he started selling his self-made sewing machine that were of a very high quality.

Even as a boy, John Reece showed a natural understanding for anything mechanical. Before reaching the age of twenty, he had built and installed an organ for his local church in Vermont.

John Reece soon found interest in sewing machines of all types and was eventually expanded his business to include repairing industrial models.

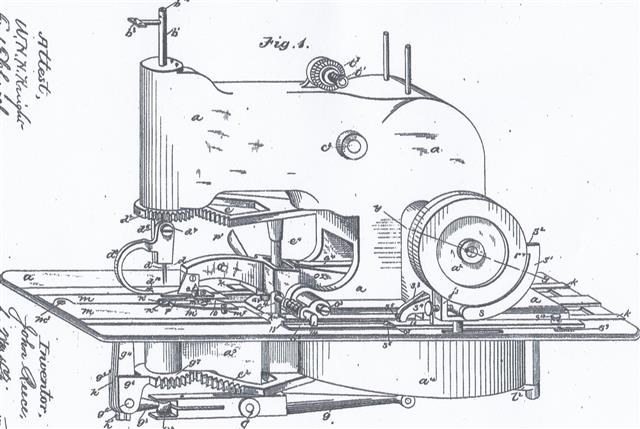

No doubt the demand for a machine with which to make buttonholes, and the appearance about this time of the laterally moving needle bar, had much to do with the creation of the hole sewing machine, but it was John Reece who developed the idea to a successful conclusion, his efforts being finally rewarded in April 1881 being granted a US Letters Patent, 240,546.

Image Reece J, from this Jubilee catalogue.

The successful development was very fast also economically successful so John Reece decided to establish a company specialized in buttonholes.

It was then he founded the "Reece button-hole sewing machine co." . The new company was registered in Portland/Maine (United States).

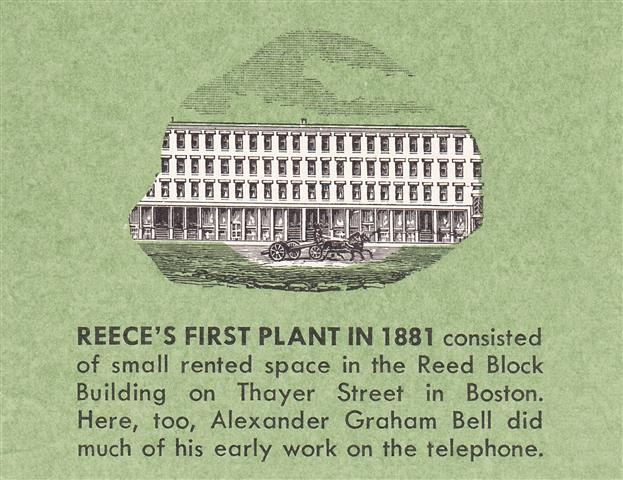

Production began in a small rented space in Boston / Massachusetts. (United States). 1881 Here, too, Alexander Graham Bell did much of his early work on the telephone.

1881 Reece first plant.

A year later in 1883 „International Button Hole Sewing Machine Company “, separately financed, was established as agent for Reece operations abroad. Since 1883 clothing manufacturers might also lease the buttonhole machines, because the new buttonhole machines were very expensive.

Clock/counting device, used on the Reece Buttonholemachines.

The big break in the business earned an award at the world exhibition in Chicago in 1893.

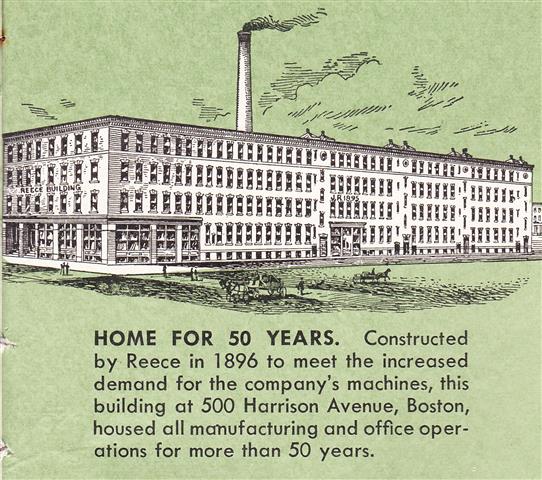

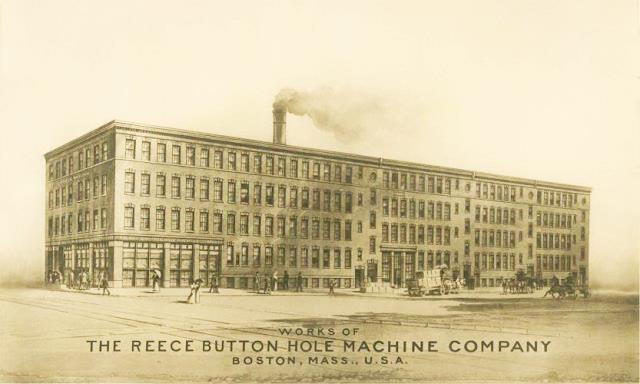

It was a big deal and in 1896 they could build new and modern manufacturing facilities in Boston.

1896 New factory.

John Reece (1854-1896) was the president of the Reece Buttonhole Machine Company in Boston, Massachusetts. In 1881 Reece invented and received a patent for a “Button Hole Sewing Machine” that revolutionized hand sewing with a machine that increased production and standardized the size of the buttonholes.

Reece lost his life 31/03/1896 when he was killed trying to save an employee in his factory, who was in danger of being crushed by a moving elevator. Reece lunged for the elevator rope, hoping to stop the elevator, but missed the cord, falling to his death.

The Reece Family Monument on Spruce Avenue was sculpted by William Ordway Partridge (1861-1930) a prominent sculptor who had studied under Pio Welenski in Rome.

In his studio on Milton Hill, a town just south of Boston, he was to model a heroic seated statue of Shakespeare that was erected in Chicago, and busts of famous Americans.

Lee Lawrie was to work as a studio assistant to Partridge in the late nineteenth century.

High honours came to John Reece’s Model J machine, among them the medal, representing the Grand Prize for all inventions exhibited at the Paris World’s Fair of 1900.

Grand Prix Paris 1900.

The big break in the business brought to Reece the years after 1908.

Everywhere new factories were built since the 19th century, where the clothing and shoe in large numbers was produced.

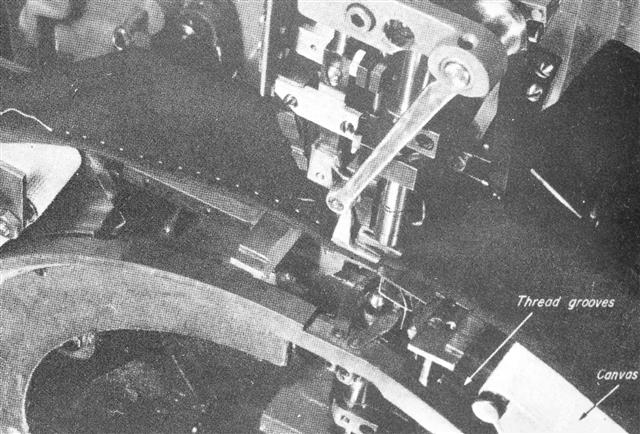

1908 high speed shoe machine. The same 2 thread overlock stitch system as the Reece J but 2-wheel drive principle greatly increased the machine’s productivity.

1908 High speed shoe machine.

1908 A New era begins in clothing manufacturing.

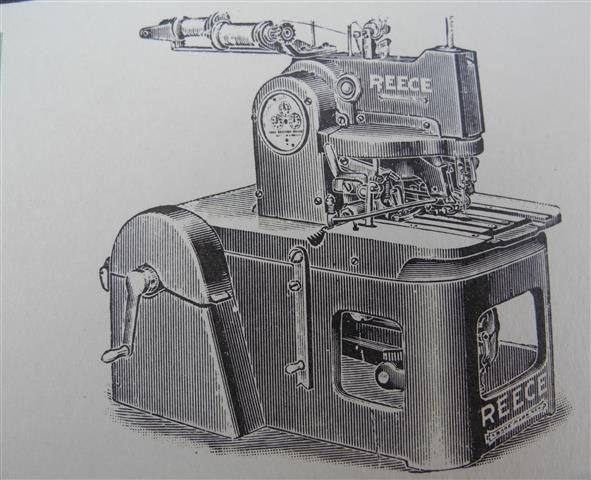

Following the turn of the 20th century, more and more factories were established as the industry began to adapt mass production methods, thus making it possible for the growing population tp buy quality clothing at low prices. Reece contributed to this progress through its development in 1908 at the "Hand-Hole Buttonhole Machine". This was the first automatic buttonhole machine designed exclusively for use in the production of tailored clothing. It became an immediate success because of its high production capacity and because the buttonholes closely resembled the work of skilled hand sewers.

1908 Reece "Hand-Hole".

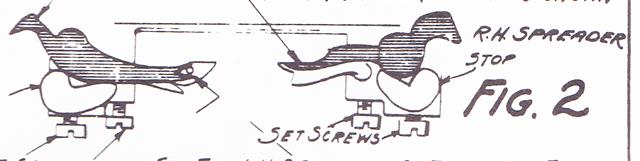

Reece Hand-Hole a machine with loopers and spreaders to build the stitch.

The name for this stitch was "Reece Stitch" and is then standard prescribed for uniforms and clothing in many countries.

1910 Came an Reece automatic button sewing machine. This automatic hopper-fed machine attached on one shoe 18 buttons in 3 seconds !??

1910 Button Sewing Machine.

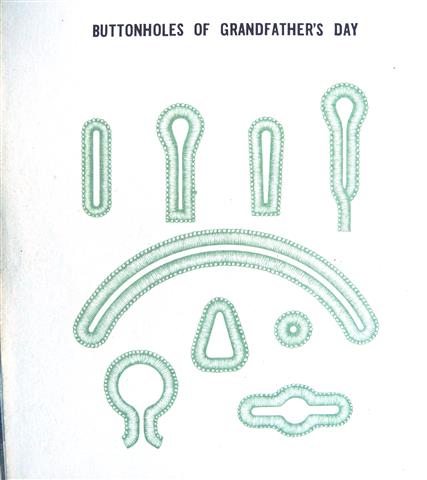

Rapid buttonhole machine of 1915. The introduction of this machine provided still greater production of standard buttonholes and specially shaped buttonholes for shoes, collars, cuffs and athletic uniforms. This machine works again with the two needle system of the Reece J.

1915 Rapid buttonhole machine.

In many respects the year around 1920 were tough years for Reece. Button shoes disappeared and detachable collars were on the way out. Some measure of this loss is recognized from an example that, 3 companies in Troye that leased 600 machines with a daily production of 5 million buttonholes were returned, the lease being cancelled.

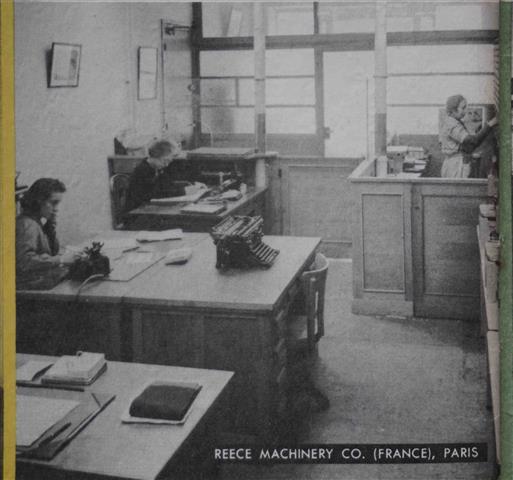

The Reece machinery Co. (France) S.A. and a branch at Melbourne, Australia and GB were opened looking for new markets.

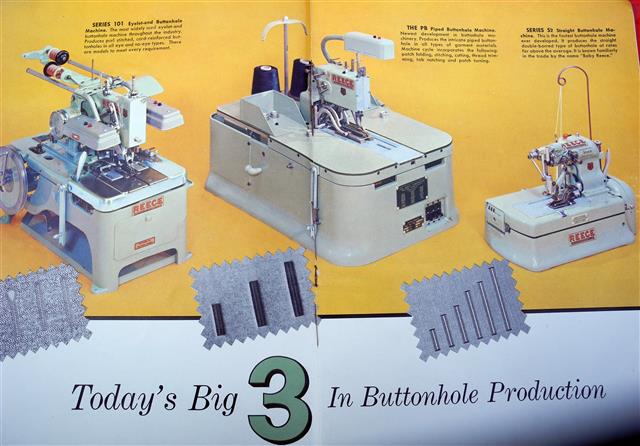

In 1935 the Model 101 was produced, and use was made of strong but light alloys replacing steel in many parts of the machine.

1935 Reece Model 101.

In 1940 a new fast, single-thread straight- buttonhole machine was produced. this new machine was named S1.

In 1945 the revised model, but now with greater speed was re-introduced as Model S2.

1945 Reece S2.

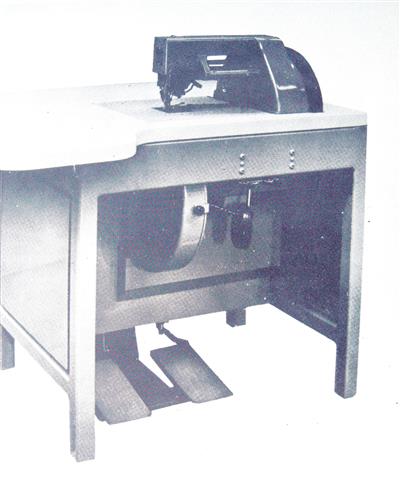

1952 Reece PB. Piped Buttonhole machine was introduced.

„The Machine that couldn’t be built”.

After years of development and extensive field tests, a Reece piped-buttonhole machine was introduced to the trade in 1952.

In additions to this being the first machine of his kind , it combined, hydraulic, electromagnetic and mechanical actions all under electric control.

1952 Reece PB.

Delivery program Reece 1956.

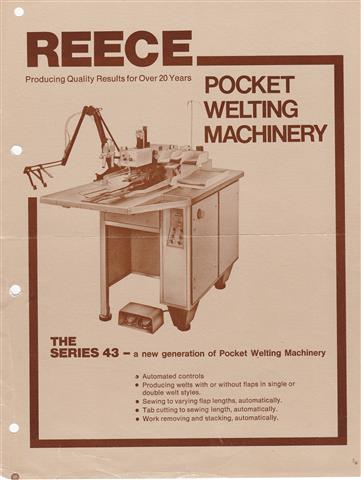

In 1958 Reece produced the pocket-welt machine for making the jetted openings of pocket in suits. This was an extension of the PB but on larger scale and using an improved hydraulic and pneumatic system.

More recent model Reece PW.(1980?)

Afbeelding van een Reece PocketWelting machine uit +/- 1980:

In the late 50s extra machine factories were founded because of high demand. Two in America and one in the Netherlands. The factory in Leiden NL. was building Reece buttonhole machines from 1959 to 1994.

Ad staff Reece Leiden NL.

Wooden transport crate Reece Leiden.

Reece has survived the so-called "great dying of companies", first worked with AMF together and later also joined Minerva CZ.

The most interesting development of the 1930s was the American Machine & Foundry (AMF) company’s pick-stitching machine, which employed the “floating “double-pointed centre-eye needle.

The needle was exactly the same as when Weisenthal first used it in 1755.

AMF needle:

AMF calls it "floating needle". The needle is inserted into the material, touched bottom, top released, material will be transported to a stitch, thread pulled and the needle is again inserted from below, touched up, etc, etc.

AMF “Floatingneedle” machine:

AMF stitching with open front.

1960 AMF first floating needle automatic button stitch machine to sew buttons on to a jacket, as if sewed by hand.

Minerva from 1871, is also a very old and well-known company.

The production and main office of AMF Reece is nowadays at the Minerva factory in the Czech Republic.

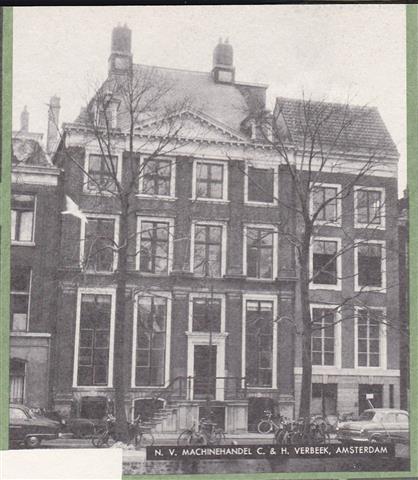

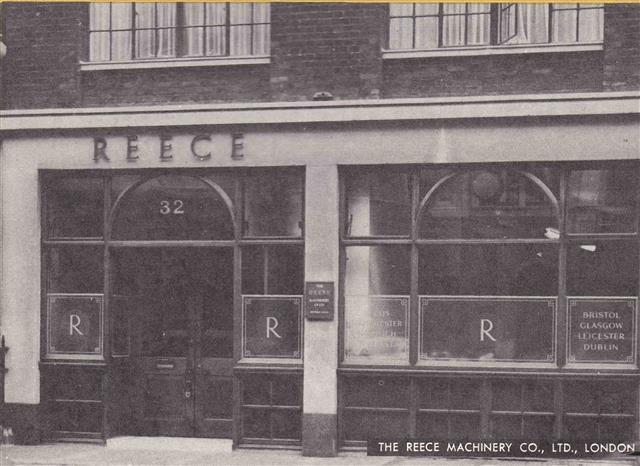

Some Reece representations in different countries.

C.H. Verbeek Amsterdam

Reece Paris, since 1920.

Reece Londen since 1914.

Berzack Bros. Johannesburg.

Fritz Zellweger Zürich.

Reece Frankfurt since 1935.

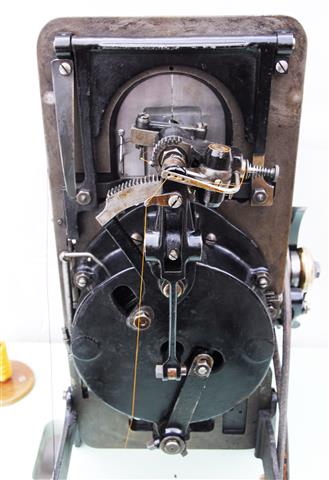

Now back to my Reece J:

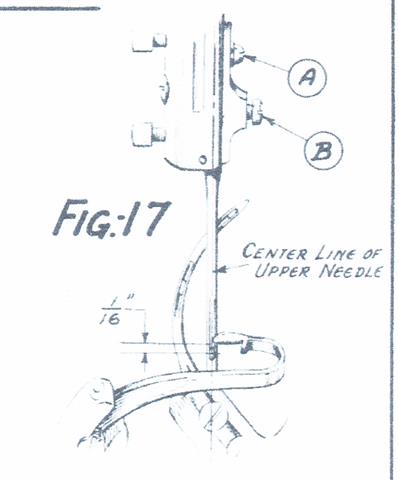

Greatly enlarged under needle.

Needle front and backside.

Needle box.

Instruction manual Reece Rapid, this part the same as Reece J.

Sources:

1956 The Reece Corporation “The Reece Story”

1982 Frank P. Godfey “An International History of the Sewing Machine”